EP

Angle Gearbox

Angle Gearbox

Gearbox has a wide range of applications, such as the application in wind turbine. Gearbox is an important mechanical component widely used in wind turbine. Its main function is to transfer the power generated by the wind wheel under the action of wind to the generator and make it get the corresponding speed.

Usually, the speed of the wind wheel is very low, which is far from the speed required by the generator. It must be realized through the speed increasing effect of the gear pair of the gearbox, so the gearbox is also called the speed increasing box.

Anale Gear Box

Noise treatment

One

Gear design. Improper parameter selection, too small overlap, improper or no profile modification, unreasonable gearbox structure, etc. In gear processing, the pitch error and tooth profile error are too large, the backlash is too large, and the surface roughness is too large.

Two

Gear train and gearbox. Assembly eccentricity, low contact accuracy, poor parallelism of shaft, insufficient stiffness of shaft, bearing and support, low rotation accuracy and improper clearance of bearing, etc.

Three

Input torque from other aspects. Fluctuation of load torque, torsional vibration of shafting, balance of motor and other transmission pairs, etc.

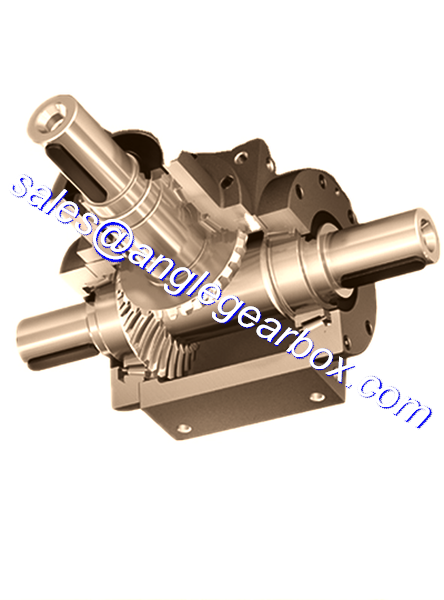

high quality right angle spiral bevel gear steering box with shaft

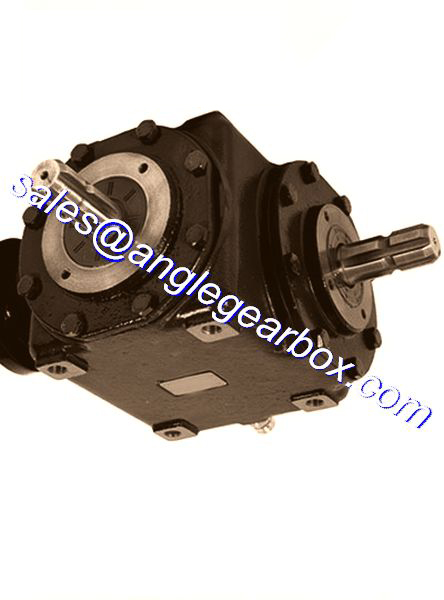

Discount price Aokman gear box K series 90 degree gearbox

Angle Gear Box

lubrication

Common lubrication methods of gearbox

There are gear oil lubrication, semi fluid grease lubrication, solid lubricant lubrication several ways. Gear oil can be used for better sealing, high speed, large load and good sealing performance; semi fluid grease can be used for poor sealing and low speed; molybdenum disulfide superfine powder can be used for no oil or high temperature occasions.

In summer, the wind turbine is in full power for a long time

In addition, the operating temperature of oil products rises above the set value due to high altitude and direct sunlight. However, when used in the northeast cold region in winter, the minimum temperature often reaches below – 30 ℃, the lubricating oil flow in the lubrication pipeline is not smooth, and the lubrication of gears and bearings is not sufficient, resulting in the high temperature shutdown of the gearbox, the wear of gear surfaces and bearings. In addition, the low temperature will also increase the viscosity of the gearbox oil and cause the oil pump to start When the load is heavy, the oil pump motor is overloaded.

The lubrication system of gear box is very important to the normal operation of gear box

Curabitur aliquet quam id dui posuere blandit. Nulla quis lorem ut libero malesuada feugiat. Vestibulum ac diam sit amet quam vehicula elementum sed sit amet dui. Donec rutrum congue leo eget malesuada. Curabitur non nulla sit amet nisl tempus convallis quis ac lectus.

All gearbox lubricants have the best operating temperature range

It is suggested to design a lubricating oil thermal management system for the gearbox lubrication system: when the temperature exceeds a certain value, the cooling system starts to work, when the temperature is lower than a certain value, the heating system starts to work, and the temperature is always controlled in the best range. In addition, improving the quality of lubricating oil is also an important aspect that must be considered in the lubrication system. Lubricant products must have excellent low-temperature fluidity and high-temperature stability. It is necessary to strengthen the research on high-performance lubricating oil.

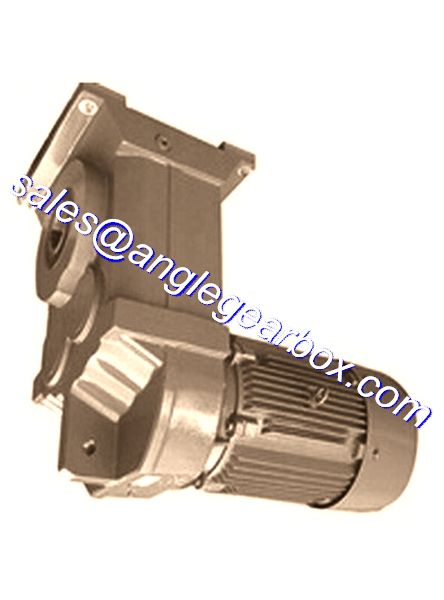

Function of angle gearbox

angle gear box

Manufacturing technology

One

The external gear of wind power gearbox generally adopts carburizing quenching grinding process. With the introduction of a large number of high-efficiency and high-precision CNC gear grinding machines, there is no big gap between China and foreign countries in gear finishing level, and there is no technical difficulty in reaching the 5-level accuracy specified in 19073 standard and 6006 standard.

Two

Due to the large size and high machining accuracy of the gear ring of the wind power gearbox, the manufacturing technology of the internal gear ring in China is far behind the international advanced level, which is mainly reflected in the aspects of gear making and heat treatment deformation control of the helical internal gear.

Three

The machining accuracy of box, planetary carrier, input shaft and other structural parts has a very important impact on the meshing quality of gear transmission and bearing life. The assembly quality also determines the life and reliability of wind turbine gearbox.

Angle Gear Box

More