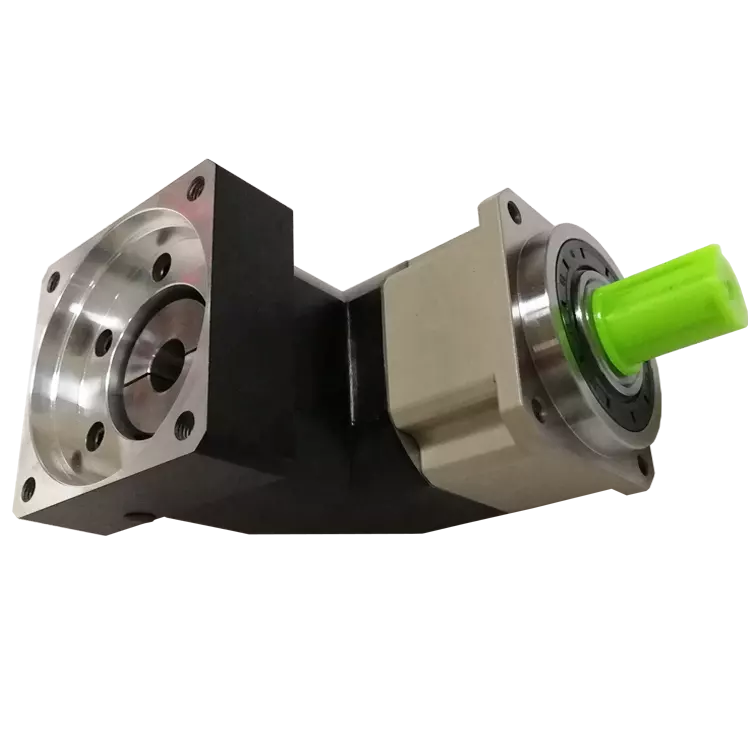

Product Description

Right Angle Speed Reducer Planetary Gearbox

Technical Parameter:

Output Torque Range: 1000 to 450,000 N.m

Transmissible Mechanical Power: up to 450 kW

Gear Ratios: 3 to 9000

Gear Unit Versions:

In line (Co-axial )

Right angle (with a spiral bevel gear set)

Output Configuration:

Foot and flange mounted

Output shaft: CHINAMFG with key, spline, spline hollow,

Hollow with shrink disc

Input Configurations

Flanged axial piston hydraulic motors

Hydraulic orbit motors

IEC and NEMA motor adaptors

Solid input shaft

Hydraulic Brake: Hydraulically released parking brake on request

|

Equivalent To Other Brand : |

|

|

Bonfiglioli |

300 Series |

|

Brevini |

EM/ED/ET/ET |

|

Dynamic oil |

RE Series |

|

REGGIANA RIDUTTOR |

RR Series |

Application:

N series planetary speed reducer is widely used for industrial applications. With the designs deriving from modern innovating, the product makes great progress in a compact, price effectiveness and combination. The product configuration is highly versatile due to several options as far as the mounting, the output shaft and the motor interface. With overloading bearing fixed to the output shaft, the products has been 1 of the powerful solutions to heavy-duty drive problems.

FAQ

-

- Q: What is your business type?

A: CHINAMFG is gearbox manufacturer and Solutions Provider, we are experts of the planetary

gear reducer, cone worm gearbox, modular design helical gear motor, worm gearbox etc.

A suitable model will offer to you according to your requirement, besides, CHINAMFG also has professional technical team specializes in the custom gearbox and gearbox repair.

-

- Q: How long can you provide products guarantee Period?

A: Based on different gearbox types, 12-18 months.

-

- Q: What’s Certification your product acquire?

A: DNV-ISO9001: 2008, SGS, CE etc. and new products patent.

-

- Q: How many technical employees in your company?

A: We have 10 engineers in our R&D Dep., included 1 engineers who enjoy government ‘s allowance.

-

- Q: Where is your company & how to contact you?

A: Our factory located in No.879 , JinLiu Rd, JinShan District , ZheJiang City , China .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Four-Step |

| Samples: |

US$ 2000/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Energy Efficiency Contribution of Angle Gearboxes

Angle gearboxes play a crucial role in enhancing energy efficiency in various machinery and equipment by:

- Optimized Power Transmission: Angle gearboxes efficiently transmit power between non-aligned input and output shafts, minimizing energy losses due to misalignment.

- Reduced Friction: Precision-engineered gear tooth profiles and high-quality lubrication reduce friction and energy dissipation within the gearbox.

- Customizable Gear Ratios: Tailoring gear ratios to specific applications allows for optimal matching of output speed and torque requirements, minimizing unnecessary energy consumption.

- Minimized Backlash: Advanced designs and manufacturing techniques in angle gearboxes reduce backlash, leading to smoother operation and improved energy efficiency.

- Compact Designs: Angle gearboxes enable space-saving layouts and component integration, enhancing overall system efficiency.

- High-Quality Bearings: Quality bearings reduce friction and ensure efficient rotation of gears, contributing to energy-efficient operation.

- Customizable Designs: Manufacturers offer angle gearbox designs optimized for specific tasks, allowing users to select the most energy-efficient solution.

- Lubrication Efficiency: Proper lubrication in angle gearboxes reduces internal losses due to friction and enhances overall energy efficiency.

- Minimized Heat Generation: Efficient power transmission and reduced friction in angle gearboxes result in less heat generation, further improving energy efficiency.

By effectively managing power transmission, reducing energy losses, and offering customizable solutions, angle gearboxes contribute significantly to the energy efficiency of various machinery and equipment.

Usage of Angle Gearboxes in Right-Angle and Bevel Gear Applications

Angle gearboxes are versatile components that can be effectively used for both right-angle and bevel gear applications. Here’s how they are utilized in each context:

Right-Angle Applications: Angle gearboxes are commonly used in right-angle applications where there is a need to transmit motion at a 90-degree angle. They efficiently change the direction of rotational motion without the need for additional components or complex mechanical arrangements. This makes them suitable for various industrial machinery, conveyors, and equipment where space constraints and changes in motion direction are important considerations.

Bevel Gear Applications: Angle gearboxes are also employed in bevel gear applications. Bevel gears are used to transmit motion between intersecting shafts, and angle gearboxes with bevel gears are designed to handle this type of motion transmission. They can efficiently transfer motion and torque between shafts that are not parallel, enabling smooth power transmission even when the input and output shafts are at an angle other than 90 degrees.

Whether it’s changing the direction of motion in right-angle applications or facilitating motion transmission between non-parallel shafts in bevel gear applications, angle gearboxes play a crucial role in ensuring efficient and reliable mechanical operations.

Handling Variations in Input and Output Angles with Angle Gearboxes

Angle gearboxes are specifically designed to handle variations in input and output angles, allowing for efficient redirection of rotational motion. They achieve this through the use of bevel gears and hypoid gears. Here’s how they handle such variations:

- Bevel Gears: Angle gearboxes equipped with bevel gears can handle changes in input and output angles by using intersecting axes. These gears have conical shapes and teeth that are cut along the cone surface. When the input shaft’s bevel gear meshes with the output shaft’s bevel gear, the intersecting angles allow for smooth power transmission even when the axes are not aligned.

- Hypoid Gears: Hypoid gear arrangements in angle gearboxes can handle larger variations in input and output angles compared to bevel gears. Hypoid gears have helical teeth and axes that are offset from each other. This offset allows for greater flexibility in handling non-parallel input and output shafts.

By employing these gear types, angle gearboxes can effectively manage variations in input and output angles, ensuring that rotational motion is smoothly redirected without compromising efficiency or causing excessive wear on the gears.

editor by CX 2024-05-06