Product Description

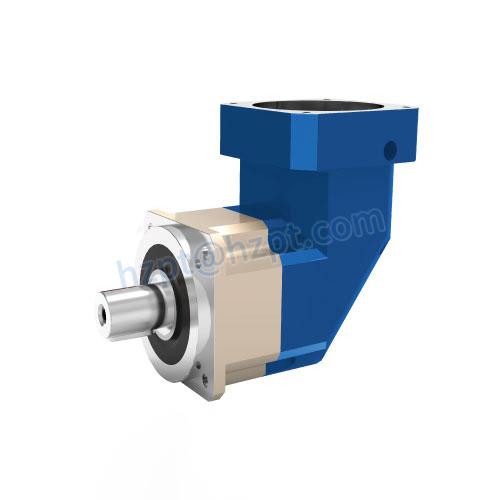

Planetary Series High Power Gear Box

Housing is made of cast iron,which improve its rigidity and anti-vibration.

Sun and plant gears are processed by cementite and hardening,gears are processes by grinding,which improve the efficiency and lifetime of the gearbox.

Input mode:coaxial input,helical gear input,bevel-helical gear input.

Output mode:internal involute spline,hollow shaft with shrink disk,external involute spline,solid shaft with flat key.

Mounting mode:Horizonal vertical,torque-arm.

P series sizes 9~34 transmission stage:2~3 ratio:25~4000

Ratio will be larger in combination with H,R,K series.

RFQ

Q:Are you trading company or manufacturer?

A: We are manufacturer with over 20 years’ experience.

Q: How long is your delivery time?

A: Generally it is within 10 days if the goods are in stock, for goods produced as per order, it is within 35 days after confirmation of order.

Q: How long should I wait for the feedback after I send the enquiry?

A: Normally within 12 hours.

Q: What information should I give you to confirm the product?

A: Model/Size, Transmission Ratio, Speed, Shaft directions & Order quantity etc.

Q: Hong long is your product warranty?

A: We offer 12 months warranty from departure date of the goods.

Q: What is your payment terms? T/T 100% in advance for amount less than USD10000.-, 30% T/T in advance , balance before shipment for amount above USD10000.

If you have any other questions, please feel free to contact us below:

HOW TO CONTACT US?

Send your Inquiry Details in the Below, click “Send” Now!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction |

| Layout: | P |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Four-Step |

| Customization: |

Available

| Customized Request |

|---|

Customization of Angle Gearboxes for Industrial Needs

Yes, angle gearboxes can be customized to meet specific industrial needs and requirements. Manufacturers offer customization options to tailor angle gearboxes to the unique demands of various applications:

- Gear Ratio Selection: Gear ratio customization allows the gearbox to achieve the desired speed reduction or increase based on the specific application’s requirements.

- Mounting Configurations: Manufacturers can design angle gearboxes with various mounting options to ensure seamless integration into different machinery setups.

- Output Shaft Options: Customizing the output shaft design enables compatibility with specific components or systems.

- Sealing and Protection: Gearboxes can be customized with specialized sealing and protection mechanisms to ensure optimal performance in harsh environments.

- Materials and Coatings: Depending on the application’s demands, manufacturers can select appropriate materials and coatings for enhanced durability and corrosion resistance.

- Special Features: Custom features such as built-in sensors, lubrication systems, or noise reduction measures can be added to meet specific operational requirements.

Customization ensures that angle gearboxes can effectively fulfill their intended roles in various industries, from automotive and aerospace to robotics and manufacturing. By tailoring the gearbox design to match specific needs, companies can achieve optimal performance, efficiency, and reliability in their applications.

Impact of Gear Ratios on Performance of Angle Gearboxes

Gear ratios play a significant role in determining the performance of angle gearboxes. The gear ratio is a measure of how many revolutions the input shaft makes compared to the output shaft. Here’s how gear ratios impact the performance:

Torque and Speed Relationship: The gear ratio directly affects the relationship between torque and speed. In an angle gearbox, a higher gear ratio (such as 1:5) means that the output shaft will rotate fewer times than the input shaft but with greater force. Conversely, a lower gear ratio (such as 5:1) results in the output shaft spinning more times but with less force. This relationship is crucial for adapting the gearbox to specific application requirements.

Power Transmission: The right choice of gear ratio ensures efficient power transmission. If a high torque is required, a lower gear ratio is chosen to provide mechanical advantage. On the other hand, a higher gear ratio is selected for applications where higher rotational speed is essential. The gear ratio determines how effectively the gearbox can convert input power into the desired output power.

Application Adaptation: Gear ratios allow angle gearboxes to adapt to various applications. Different tasks require different combinations of torque and speed. By selecting the appropriate gear ratio, the gearbox can tailor its output to suit the specific demands of the task, optimizing efficiency and performance.

Overall, gear ratios in angle gearboxes provide a way to fine-tune the output characteristics, allowing them to fulfill a wide range of mechanical requirements across different industries and applications.

Variations in Angle Gearbox Designs for Specific Tasks and Applications

Yes, angle gearbox designs can vary to suit specific tasks and applications across different industries. Manufacturers offer a range of angle gearbox configurations to address various requirements. Some common variations include:

- Right Angle Gearboxes: These angle gearboxes have input and output shafts at a 90-degree angle. They are often used in applications where space is limited, such as conveyor systems and packaging machinery.

- Worm Gear Angle Gearboxes: These gearboxes incorporate a worm gear arrangement, providing high gear reduction ratios. They are suitable for applications that require precise speed control, such as conveyor systems and material handling equipment.

- Bevel Gear Angle Gearboxes: Bevel gearboxes use intersecting shafts and conical gears to redirect motion at different angles. They are commonly found in automotive drivetrains, printing machines, and power tools.

- Hypoid Gear Angle Gearboxes: Hypoid gearboxes feature offset axes and helical gear teeth, allowing them to handle larger variations in input and output angles. They are used in automotive applications, heavy machinery, and industrial equipment.

- Customized Angle Gearboxes: Some manufacturers offer customized angle gearbox solutions tailored to specific applications. These gearboxes are designed to meet unique requirements, such as specific torque, speed, or space limitations.

Overall, the variations in angle gearbox designs enable them to be versatile and adaptable to a wide range of tasks and applications, making them an essential component in many industries.

editor by CX 2024-04-17