Product Description

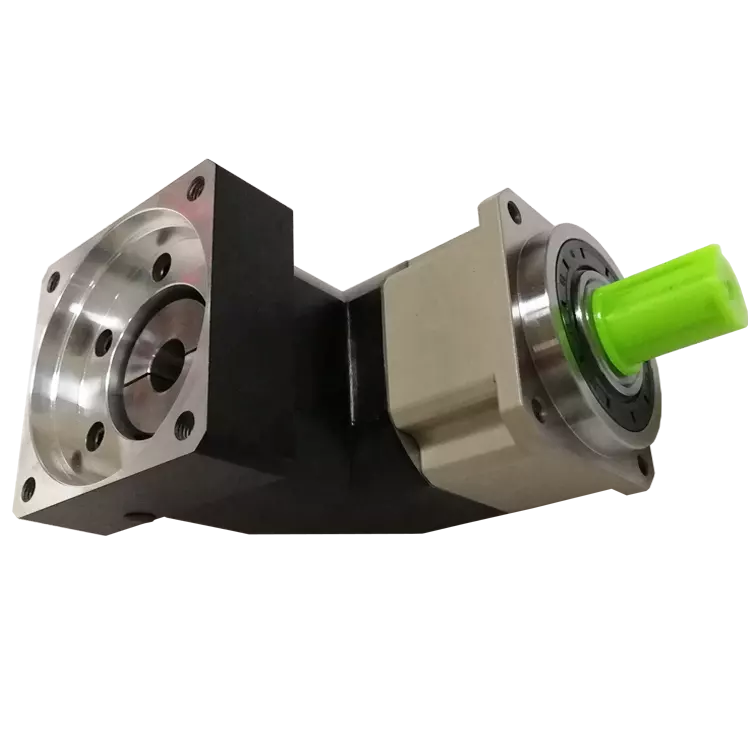

Right Angle Input Round Mounting Flange High Precision Planetary Gear Box, Small Gearbox Manufacture

Planetary gearbox:

ZDE: Precision planetary-round flange output

ZDF: Precision planetary-square flange output

ZDWE: Precise planetary-right angle round flange output

ZDWF: Precise planetary-right angle square flange output

ZDS: Precise planetary-high rigidity, low back lash

| ZDE | round mounting flange |

| ZDWE | right angle input round mounting flange |

| ZDF | square mounting flange |

| ZDWF | right angle input square mounting flange |

| ZDS | high stiffness series |

| Gear Ratio: | |

| single stage | 3, 4, 5, 8, 10 |

| two stages | 9, 12, 15, 16, 20, 25, 32, 40, 64 |

| three stages | 60, 80, 100, 120, 160, 200, 256, 320, 512 |

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

More about our products and company:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Power, Electronic |

|---|---|

| Phase: | NONE |

| Core: | NONE |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Optimizing Conveyor System Efficiency with Angle Gearboxes

Angle gearboxes play a crucial role in enhancing the efficiency of conveyor systems in various industries:

1. Direction Changes: Conveyor systems often require changes in direction to navigate through a facility. Angle gearboxes enable smooth and precise redirection of the conveyor belts without causing unnecessary strain on the system.

2. Speed Control: Angle gearboxes allow for precise adjustment of the rotational speed of conveyor belts. This is essential for maintaining consistent material flow and preventing jams or spillage.

3. Load Distribution: In large conveyor systems, loads may not be evenly distributed. Angle gearboxes can help balance the load distribution among multiple conveyor belts, optimizing the system’s overall efficiency.

4. Motion Synchronization: When multiple conveyor belts work in tandem, angle gearboxes ensure synchronized movement, preventing collisions and optimizing the overall workflow.

5. Vertical Conveying: Incline or decline conveyor sections require precise control to prevent items from sliding or tumbling. Angle gearboxes provide the necessary torque and control for efficient vertical movement.

6. Compact Design: Angle gearboxes’ compact and space-saving design allows conveyor systems to be efficiently integrated into existing production layouts.

7. Energy Efficiency: By optimizing motion control and reducing friction losses, angle gearboxes contribute to energy-efficient conveyor operation.

8. Reduced Maintenance: Well-designed angle gearboxes minimize wear and tear, leading to reduced maintenance needs and extended system lifespan.

By incorporating angle gearboxes into conveyor systems, industries can achieve smoother operation, precise control, energy savings, and overall increased productivity.

Usage of Angle Gearboxes in Right-Angle and Bevel Gear Applications

Angle gearboxes are versatile components that can be effectively used for both right-angle and bevel gear applications. Here’s how they are utilized in each context:

Right-Angle Applications: Angle gearboxes are commonly used in right-angle applications where there is a need to transmit motion at a 90-degree angle. They efficiently change the direction of rotational motion without the need for additional components or complex mechanical arrangements. This makes them suitable for various industrial machinery, conveyors, and equipment where space constraints and changes in motion direction are important considerations.

Bevel Gear Applications: Angle gearboxes are also employed in bevel gear applications. Bevel gears are used to transmit motion between intersecting shafts, and angle gearboxes with bevel gears are designed to handle this type of motion transmission. They can efficiently transfer motion and torque between shafts that are not parallel, enabling smooth power transmission even when the input and output shafts are at an angle other than 90 degrees.

Whether it’s changing the direction of motion in right-angle applications or facilitating motion transmission between non-parallel shafts in bevel gear applications, angle gearboxes play a crucial role in ensuring efficient and reliable mechanical operations.

Handling Variations in Input and Output Angles with Angle Gearboxes

Angle gearboxes are specifically designed to handle variations in input and output angles, allowing for efficient redirection of rotational motion. They achieve this through the use of bevel gears and hypoid gears. Here’s how they handle such variations:

- Bevel Gears: Angle gearboxes equipped with bevel gears can handle changes in input and output angles by using intersecting axes. These gears have conical shapes and teeth that are cut along the cone surface. When the input shaft’s bevel gear meshes with the output shaft’s bevel gear, the intersecting angles allow for smooth power transmission even when the axes are not aligned.

- Hypoid Gears: Hypoid gear arrangements in angle gearboxes can handle larger variations in input and output angles compared to bevel gears. Hypoid gears have helical teeth and axes that are offset from each other. This offset allows for greater flexibility in handling non-parallel input and output shafts.

By employing these gear types, angle gearboxes can effectively manage variations in input and output angles, ensuring that rotational motion is smoothly redirected without compromising efficiency or causing excessive wear on the gears.

editor by CX 2024-04-09