Product Description

Product Description

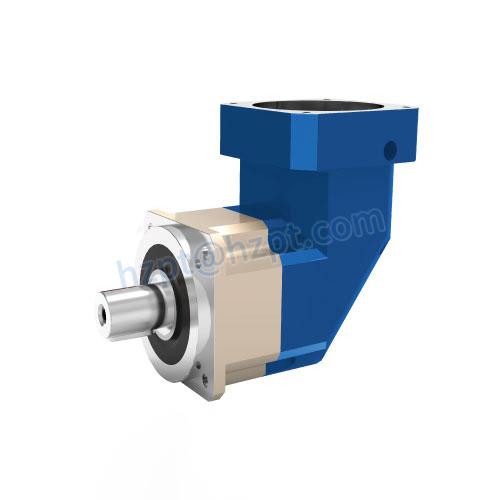

High Torque CHINAMFG right angle Planetary Gear Box Can Replace Bonfigiloli and CHINAMFG model

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output | solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

Packing Pictures :

Factory

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Ensuring Precision of Gear Tooth Profiles in Angle Gearboxes

Manufacturers employ various techniques and processes to ensure the precision of gear tooth profiles in angle gearboxes:

- Advanced Manufacturing Technologies: Modern manufacturing technologies such as CNC machining and gear hobbing are used to precisely shape gear teeth. Computer-controlled processes enable accurate replication of gear tooth profiles.

- High-Quality Materials: High-quality materials are selected to create gears that can withstand the stresses and loads they will experience during operation. High-grade metals and alloys are commonly used.

- Quality Control and Inspection: Rigorous quality control measures involve inspecting gear tooth profiles using specialized equipment like coordinate measuring machines (CMMs) and gear analyzers. This ensures that the dimensions and profiles meet the required specifications.

- Tooth Profile Design Software: Engineering software is used to design gear tooth profiles with precision. Computer-aided design (CAD) software allows engineers to model gear teeth accurately before manufacturing.

- Heat Treatment: Gears are often subjected to heat treatment processes such as carburizing or nitriding to enhance their surface hardness, durability, and resistance to wear.

The combination of advanced manufacturing techniques, strict quality control, and the use of quality materials helps manufacturers achieve the necessary precision in gear tooth profiles. This precision is critical to ensure smooth and efficient power transmission, minimal noise, and extended gearbox lifespan.

Selecting the Right Angle Gearbox for an Application

Choosing the appropriate angle gearbox for a specific application involves considering several key factors to ensure optimal performance and reliability:

- Application Requirements: Determine the required torque, speed, and power output of the gearbox to match the demands of the application.

- Input and Output Angles: Identify the desired input and output angles for the gearbox to ensure it can effectively redirect motion as needed.

- Space Constraints: Evaluate the available space to select a gearbox that fits within the allocated area.

- Gearbox Type: Choose the suitable gearbox type (e.g., right angle, bevel, worm, hypoid) based on the application’s specific needs.

- Load Conditions: Consider factors such as load variation, shock loads, and continuous vs. intermittent operation to determine gearbox durability.

- Environmental Conditions: Account for factors like temperature, humidity, and exposure to contaminants, which can affect gearbox performance and lifespan.

- Efficiency: Evaluate the gearbox’s efficiency, as lower efficiency may result in more energy consumption and heat generation.

- Mounting and Installation: Ensure that the gearbox can be easily mounted and integrated into the existing system.

- Maintenance and Servicing: Consider the ease of maintenance, accessibility to components, and availability of replacement parts.

- Budget: Compare the cost of the gearbox with its features and benefits to determine its overall value for the application.

By carefully considering these factors, engineers and designers can select the right angle gearbox that best meets the requirements of the specific application, ensuring optimal performance and longevity.

Types of Angle Gearboxes and Their Functions

Angle gearboxes, also known as bevel gearboxes, come in different types, each designed for specific functions and applications. The various types of angle gearboxes include:

- Straight Bevel Gearbox: This type of angle gearbox features straight-cut bevel gears with intersecting shafts set at a 90-degree angle. It is commonly used for changing the direction of rotational motion in applications such as automotive differentials and power tools.

- Spiral Bevel Gearbox: Spiral bevel gearboxes utilize spiral-cut bevel gears that offer smoother and quieter operation compared to straight-cut gears. They are employed in applications where reduced noise and improved load-carrying capacity are important, such as in heavy machinery and vehicles.

- Skew Bevel Gearbox: Skew bevel gearboxes have shafts set at an angle other than 90 degrees. They are used in applications where the intersecting shafts do not align at a right angle. Skew bevel gears are often found in industrial machinery and equipment that requires a specific angle of transmission.

- Hypoid Gearbox: Hypoid gearboxes feature hypoid gears, which are a variation of bevel gears with offset axes. This design allows the gears to mesh smoothly while reducing noise and increasing torque transmission efficiency. Hypoid gearboxes are commonly used in automotive applications like rear-wheel-drive systems.

- Angular Bevel Gearbox: Angular bevel gearboxes are designed for applications where the angle between the input and output shafts is adjustable. They are used in situations where the desired transmission angle can be changed to achieve specific mechanical requirements.

Each type of angle gearbox serves a distinct purpose, catering to various industries and applications. Their designs are optimized to provide efficient motion transmission, reliable performance, and the ability to accommodate different angles and loads.

editor by CX 2024-04-25