Product Description

Product Description

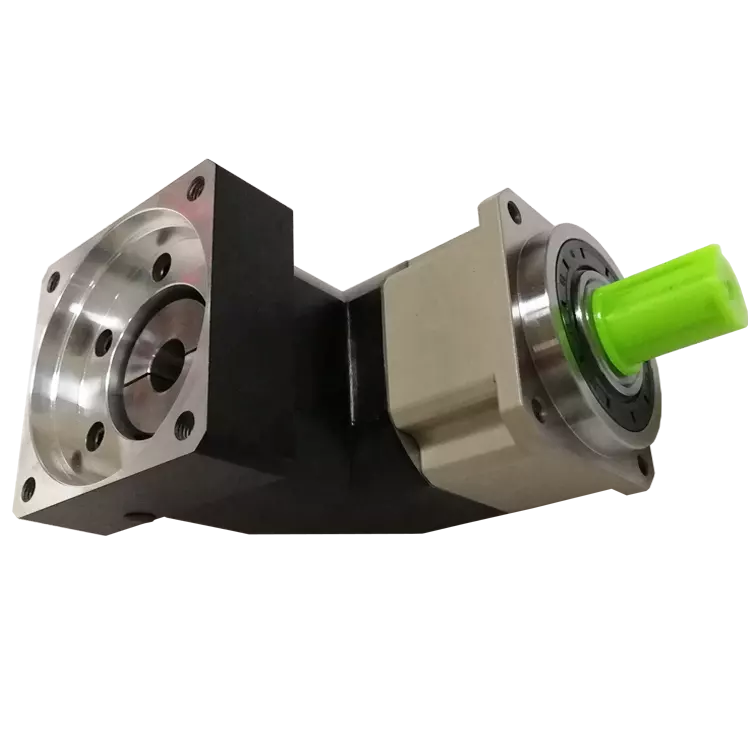

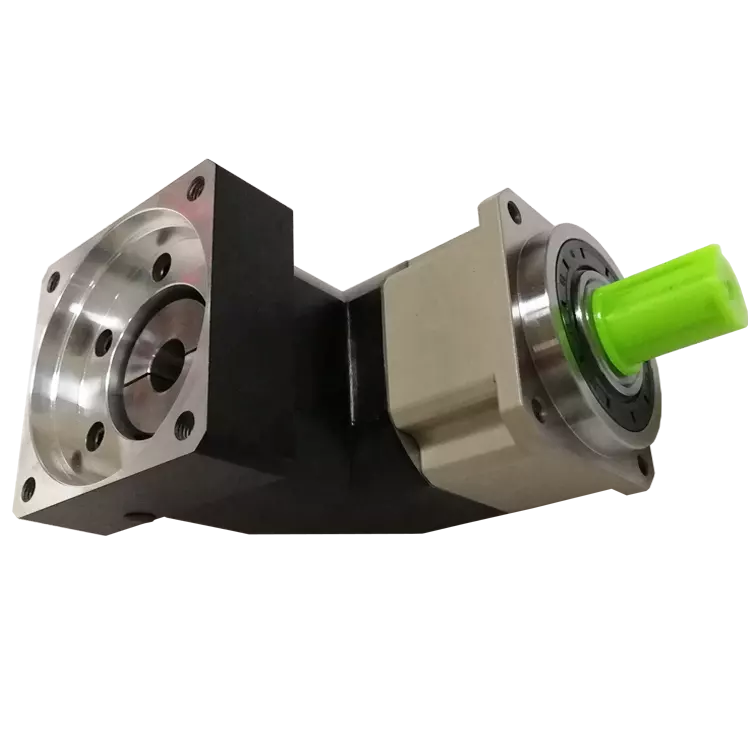

Original manufacturer exports right angle reducer and high-precision planetary reducer

Low noise: less than 65db.

Low back clearance: up to 3 arc minutes in a CHINAMFG and 5 arc minutes in a double stage.

High torque: higher than the standard planetary reducer torque.

High stability: high strength alloy steel, the whole gear after hardening treatment, not only the surface hard substitution.

High deceleration ratio: Modular design, planetary gearbox can be interlinked.

85mm L1-10 Angle planetary gear box (750W servo motor) advantages:

1, compact structure: the characteristics of large torque planetary reducer is to make full use of space, limited space design bearing and gear ratio, so that the product is smaller than the traditional reducer volume can save space.

2, high efficiency: the planetary gear group will be in a completely tight meshing state when running, reducing gear collision or local meshing resulting in gear damage. The completely tight meshing characteristic makes the efficiency loss of each gear transmission only 3%. This type of transmission mode can ensure that the kinetic energy input reducer to the mechanical end of the process, still can maintain high transmission efficiency, avoid the internal gear friction, sliding, mechanical loss.

3, high axial and radial load capacity: the output shaft of Fubao technology’s high-torque planetary reducer adopts a large-span style, so that the bearing is configured at both ends of the output shaft. The design can effectively disperse the force acting on the output shaft and reduce the load of the bearing. In other words, the product strengthens the bearing and radial load capacity under the same size.

4, high strength: large torque planetary reducer gear group is very strong and stable, the thickness of the gear dispersed the load on the gear. The large span bearing group provides a stable structure, and the precision gear group allows the load to be distributed to each planetary gear under tight meshing to withstand the torque load.

5, high stability: precision processing to ensure that the product coaxial and concentric, coupled with bearing large span design, so that large torque planetary reducer with excellent stability.

Detailed Photos

Product Details

Product Classification

Product Advantage

Compared with other reduction machines, planetary gear reduction machines have high rigidity, high precision (single stage can be achieved within 1 point), high transmission efficiency (single stage in 97-98%), high torque/volume ratio, lifetime maintenance free and other characteristics.

Because of these characteristics, planetary gear reducer is mostly installed on the stepper motor and servo motor, used to reduce speed, increase torque, matching inertia.

Company Profile

Factory Display

FAQ

Q: Speed reducer grease replacement time

A: When sealing appropriate amount of grease and running reducer, the standard replacement time is 20000 hours according to the aging condition of the grease. In addition, when the grease is stained or used in the surrounding temperature condition (above 40ºC), please check the aging and fouling of the grease, and specify the replacement time.

Q: Delivery time

A: Fubao has 2000+ production base, daily output of 1000+ units, standard models within 7 days of delivery.

Q: Reducer selection

A: Fubao provides professional product selection guidance, with higher product matching degree, higher cost performance and higher utilization rate.

Q: Application range of reducer

A: Fubao has a professional research and development team, complete category design, can match any stepping motor, servo motor, more accurate matching.

| Application: | Motor, Machinery, Agricultural Machinery, Robotautomatic Equipment |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Changing, Speed Reduction, Lower The Speed and Increase The Torque |

| Layout: | Coaxial |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Disadvantages and Limitations of Angle Gearbox Systems

While angle gearbox systems offer numerous advantages, there are also some disadvantages and limitations to consider:

- Complex Design: Angle gearboxes can have a more complex design compared to standard gearboxes, which can make them harder to manufacture, assemble, and maintain. This complexity can also lead to higher production costs.

- Efficiency Loss: Due to the multiple gear stages and changes in direction of motion, angle gearboxes can experience higher friction and efficiency losses compared to straight-line gearboxes. This can result in some energy loss and heat generation.

- Space Constraints: The design of angle gearboxes often requires more space to accommodate the multiple gear stages and components, which can be a limitation in applications with limited space.

- Increased Maintenance: The complex design of angle gearboxes can lead to increased maintenance requirements. Components such as bearings, seals, and gears may need more frequent inspections and replacements.

- Cost: Angle gearboxes can be more expensive to produce and maintain due to their intricate design and the precision required in manufacturing. This can impact the overall cost of the machinery or equipment in which they are used.

Despite these limitations, angle gearbox systems are chosen when their benefits outweigh their drawbacks for specific applications. Engineers and designers carefully assess the requirements of the application to determine if an angle gearbox is the optimal solution, taking into account factors such as space availability, load demands, efficiency considerations, and budget constraints.

Efficient Power Transmission and Motion Control with Angle Gearboxes

Angle gearboxes play a crucial role in ensuring efficient power transmission and precise motion control in various mechanical systems. They achieve this through several mechanisms:

- Gear Arrangement: Angle gearboxes use a combination of gears, such as bevel gears, worm gears, or hypoid gears, to redirect the rotational motion efficiently while changing the direction of the output shaft.

- High Gear Ratios: Many angle gearboxes incorporate high gear ratios, allowing them to convert high-speed, low-torque input into lower-speed, higher-torque output. This is particularly useful in applications where high torque is required, such as heavy machinery or industrial equipment.

- Precision Engineering: Angle gearboxes are designed with precision to minimize backlash and gear play. This ensures accurate and reliable motion control, which is essential in applications demanding precise positioning and synchronization.

- Lubrication and Sealing: Proper lubrication and sealing in angle gearboxes reduce friction and wear, contributing to efficient power transmission. Well-maintained gearboxes experience less energy loss due to friction and heat generation.

- Material Selection: High-quality materials and advanced manufacturing techniques are used to construct angle gearboxes. This ensures that components can handle the loads and stresses without excessive wear or failure, promoting efficient power transfer.

- Alignment and Assembly: Accurate alignment during the assembly of angle gearboxes prevents misalignment-related losses and reduces strain on gears and bearings, resulting in smoother power transmission.

Whether in industrial machinery, automotive systems, or other mechanical applications, angle gearboxes contribute to efficient power transmission and motion control by optimizing gear arrangements, minimizing energy losses, and providing reliable performance over extended periods.

Handling Variations in Input and Output Angles with Angle Gearboxes

Angle gearboxes are specifically designed to handle variations in input and output angles, allowing for efficient redirection of rotational motion. They achieve this through the use of bevel gears and hypoid gears. Here’s how they handle such variations:

- Bevel Gears: Angle gearboxes equipped with bevel gears can handle changes in input and output angles by using intersecting axes. These gears have conical shapes and teeth that are cut along the cone surface. When the input shaft’s bevel gear meshes with the output shaft’s bevel gear, the intersecting angles allow for smooth power transmission even when the axes are not aligned.

- Hypoid Gears: Hypoid gear arrangements in angle gearboxes can handle larger variations in input and output angles compared to bevel gears. Hypoid gears have helical teeth and axes that are offset from each other. This offset allows for greater flexibility in handling non-parallel input and output shafts.

By employing these gear types, angle gearboxes can effectively manage variations in input and output angles, ensuring that rotational motion is smoothly redirected without compromising efficiency or causing excessive wear on the gears.

editor by CX 2023-12-12