Product Description

Product Description

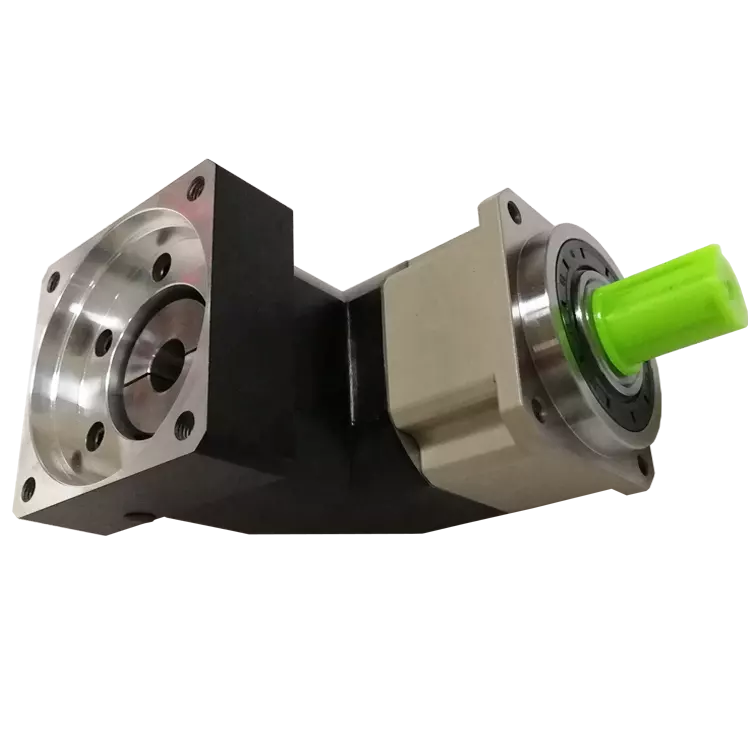

The NDR090 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The ND series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NDR090 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

1 arc minute ≤ backlash ≤ 3 arc minutes

Reduction ratios ranging from 4 to 200

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

Ultra-precision

Small size

Space saving

Detailed Photos

Product Parameters

| Segment number | Double segment | ||||||||

| Ratio | i | 25 | 35 | 40 | 50 | 70 | 100 | 140 | 200 |

| Rated output torque | Nm | 150 | 130 | 120 | 150 | 130 | 95 | 130 | 95 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||

| Rated input speed | Rpm | 4000 | |||||||

| Max input speed | Rpm | 8000 | |||||||

| Ultraprecise backlash | arcmin | ≤4 | |||||||

| Precision backlash | arcmin | ≤7 | |||||||

| Standard backlash | arcmin | ≤9 | |||||||

| Torsional rigidity | Nm/arcmin | 31 | |||||||

| Max.bending moment | Nm | 235 | |||||||

| Max.axial force | N | 2850 | |||||||

| Service life | hr | 30000(15000 under continuous operation) | |||||||

| Efficiency | % | ≥92% | |||||||

| Weight | kg | 4.5 | |||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||

| Lubrication | Synthetic grease | ||||||||

| Protection class | IP64 | ||||||||

| Mounting Position | All directions | ||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤65 | |||||||

| Rotary inertia | Kg·cm² | 0.35 | 0.31 | ||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Gearbox |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Disadvantages and Limitations of Angle Gearbox Systems

While angle gearbox systems offer numerous advantages, there are also some disadvantages and limitations to consider:

- Complex Design: Angle gearboxes can have a more complex design compared to standard gearboxes, which can make them harder to manufacture, assemble, and maintain. This complexity can also lead to higher production costs.

- Efficiency Loss: Due to the multiple gear stages and changes in direction of motion, angle gearboxes can experience higher friction and efficiency losses compared to straight-line gearboxes. This can result in some energy loss and heat generation.

- Space Constraints: The design of angle gearboxes often requires more space to accommodate the multiple gear stages and components, which can be a limitation in applications with limited space.

- Increased Maintenance: The complex design of angle gearboxes can lead to increased maintenance requirements. Components such as bearings, seals, and gears may need more frequent inspections and replacements.

- Cost: Angle gearboxes can be more expensive to produce and maintain due to their intricate design and the precision required in manufacturing. This can impact the overall cost of the machinery or equipment in which they are used.

Despite these limitations, angle gearbox systems are chosen when their benefits outweigh their drawbacks for specific applications. Engineers and designers carefully assess the requirements of the application to determine if an angle gearbox is the optimal solution, taking into account factors such as space availability, load demands, efficiency considerations, and budget constraints.

Impact of Gear Ratios on Performance of Angle Gearboxes

Gear ratios play a significant role in determining the performance of angle gearboxes. The gear ratio is a measure of how many revolutions the input shaft makes compared to the output shaft. Here’s how gear ratios impact the performance:

Torque and Speed Relationship: The gear ratio directly affects the relationship between torque and speed. In an angle gearbox, a higher gear ratio (such as 1:5) means that the output shaft will rotate fewer times than the input shaft but with greater force. Conversely, a lower gear ratio (such as 5:1) results in the output shaft spinning more times but with less force. This relationship is crucial for adapting the gearbox to specific application requirements.

Power Transmission: The right choice of gear ratio ensures efficient power transmission. If a high torque is required, a lower gear ratio is chosen to provide mechanical advantage. On the other hand, a higher gear ratio is selected for applications where higher rotational speed is essential. The gear ratio determines how effectively the gearbox can convert input power into the desired output power.

Application Adaptation: Gear ratios allow angle gearboxes to adapt to various applications. Different tasks require different combinations of torque and speed. By selecting the appropriate gear ratio, the gearbox can tailor its output to suit the specific demands of the task, optimizing efficiency and performance.

Overall, gear ratios in angle gearboxes provide a way to fine-tune the output characteristics, allowing them to fulfill a wide range of mechanical requirements across different industries and applications.

Variations in Angle Gearbox Designs for Specific Tasks and Applications

Yes, angle gearbox designs can vary to suit specific tasks and applications across different industries. Manufacturers offer a range of angle gearbox configurations to address various requirements. Some common variations include:

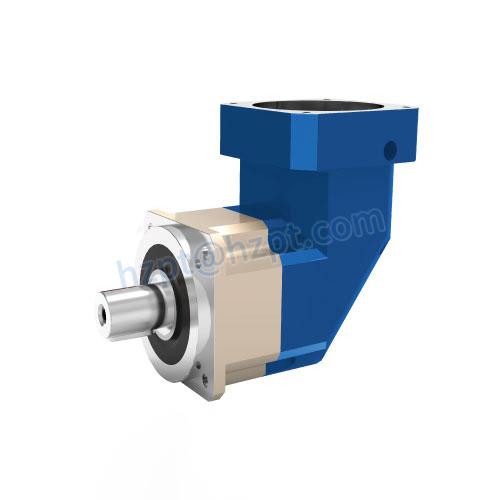

- Right Angle Gearboxes: These angle gearboxes have input and output shafts at a 90-degree angle. They are often used in applications where space is limited, such as conveyor systems and packaging machinery.

- Worm Gear Angle Gearboxes: These gearboxes incorporate a worm gear arrangement, providing high gear reduction ratios. They are suitable for applications that require precise speed control, such as conveyor systems and material handling equipment.

- Bevel Gear Angle Gearboxes: Bevel gearboxes use intersecting shafts and conical gears to redirect motion at different angles. They are commonly found in automotive drivetrains, printing machines, and power tools.

- Hypoid Gear Angle Gearboxes: Hypoid gearboxes feature offset axes and helical gear teeth, allowing them to handle larger variations in input and output angles. They are used in automotive applications, heavy machinery, and industrial equipment.

- Customized Angle Gearboxes: Some manufacturers offer customized angle gearbox solutions tailored to specific applications. These gearboxes are designed to meet unique requirements, such as specific torque, speed, or space limitations.

Overall, the variations in angle gearbox designs enable them to be versatile and adaptable to a wide range of tasks and applications, making them an essential component in many industries.

editor by CX 2023-12-08