Product Description

Product Description

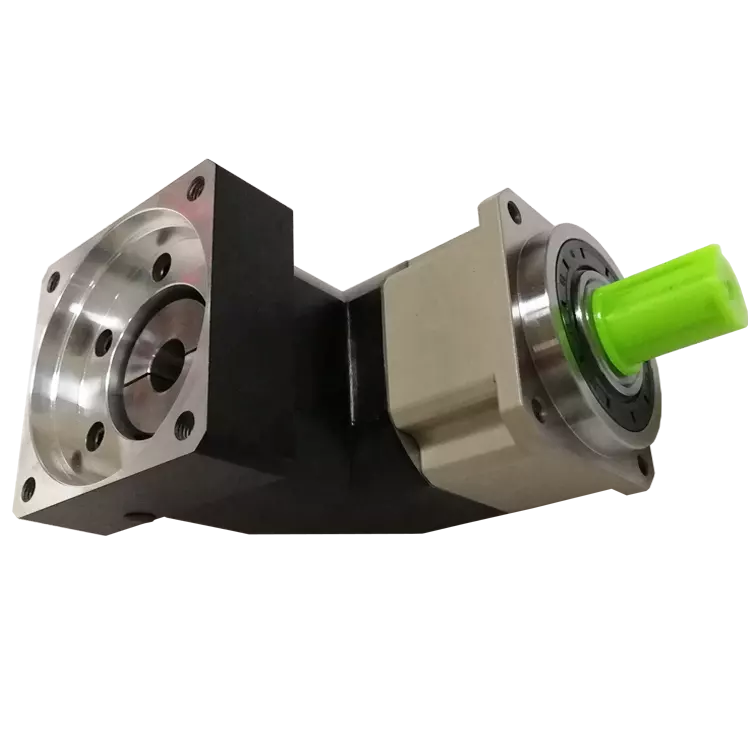

High Torque CHINAMFG right angle Planetary Gear Box Can Replace Bonfigiloli and CHINAMFG model

Technical data:

1. Ratio range: 8.1-191

2. Input power: 0.12-270 KW

3. Permit torque rang: ≤ 50000 N. M

4. Output speed: 0.3~205 r/min

5. Structure: Foot-mounted, flange-mounted, shaft-mounted

| Input structure | motor,IEC flange |

| Output | solid shaft, hollow shaft with key,with shrink disk |

Characteristic:

1. Adopt optimized design, module combination, right angle output, space reduction

2. High strength and longevity gears

3. Can be combined with various motors, wider ratio range

4. Big output torque, smoothly startup, high efficiency

Production pictures:

Packing Pictures :

Factory

———————————————————————————————————————————————

FAQ:

1.Are you a factory or trader ?

We are a professional factory which has 20 years history specialized in gear transmission .

2.MOQ:

Our MOQ is 1pcs. However there is 1 handling cost $150 for the single order which less than $3000.00

3. Warranty

Our warranty is 12months

4. Payment term

100% T/T in advance and LC at sight .

5. Do you accept customization ?

YES.SGR have strong R&D team, we can provide customizable service according to requirements.

6. Packing

Generally we use standard export plywood case to arrange the shipment .

7. Delivery time

In normal ,time of delivery is 30days after receiving the prepayment .

8. What kinds of certification do you use ?

DNV-ISO9001:2008, SGS,CE etc, And new products patent.

9. What kinds of inspection you do before shipment ?

We do temperature test, noise, and oil leak inspection and commissioning before shipment.

10.How do you solve if the production have problem ?

Mostly, we don’t need customer send the goods back to us. Because the cost is very high, if there meets a problem,we firstly ask for the pictures for damaged parts. And base on the pictures, we can have a basic idea for the defect reason. Our guarantee is 12 months, if during the guarantee, we can supply repair .

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Single-Step |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Choosing Lubrication for Angle Gearboxes

When selecting lubrication for angle gearboxes, several critical considerations should be taken into account:

- Operating Conditions: The operating environment, temperature range, and exposure to moisture or contaminants play a significant role in determining the type of lubricant needed.

- Load and Torque: The load-carrying capacity and torque requirements of the gearbox impact the choice of lubricant viscosity and additives.

- Speed: The speed of the gearbox influences the lubricant’s ability to form and maintain a protective film between gear surfaces.

- Materials: Consider the materials of the gears, bearings, and other components to ensure compatibility with the lubricant.

- Lubricant Type: Choose between oil and grease lubrication, considering factors like lubrication intervals, leakage, and sealing effectiveness.

- Viscosity: The lubricant’s viscosity should match the gearbox’s operational requirements, providing sufficient film thickness without causing excessive drag.

- Extreme Conditions: In extreme temperatures or harsh conditions, specialized lubricants with additives for high-temperature, low-temperature, or extreme-pressure performance may be necessary.

- Sealing: The gearbox’s sealing effectiveness impacts lubricant retention and protection against contaminants.

- Compatibility: Ensure that the chosen lubricant is compatible with any existing lubricants or residues to prevent chemical reactions.

- Maintenance: Consider ease of lubricant replenishment and maintenance intervals when selecting a lubrication solution.

Choosing the appropriate lubrication for angle gearboxes is essential to ensure smooth operation, minimize wear and friction, extend the gearbox’s lifespan, and maintain overall efficiency and reliability.

Usage of Angle Gearboxes in Right-Angle and Bevel Gear Applications

Angle gearboxes are versatile components that can be effectively used for both right-angle and bevel gear applications. Here’s how they are utilized in each context:

Right-Angle Applications: Angle gearboxes are commonly used in right-angle applications where there is a need to transmit motion at a 90-degree angle. They efficiently change the direction of rotational motion without the need for additional components or complex mechanical arrangements. This makes them suitable for various industrial machinery, conveyors, and equipment where space constraints and changes in motion direction are important considerations.

Bevel Gear Applications: Angle gearboxes are also employed in bevel gear applications. Bevel gears are used to transmit motion between intersecting shafts, and angle gearboxes with bevel gears are designed to handle this type of motion transmission. They can efficiently transfer motion and torque between shafts that are not parallel, enabling smooth power transmission even when the input and output shafts are at an angle other than 90 degrees.

Whether it’s changing the direction of motion in right-angle applications or facilitating motion transmission between non-parallel shafts in bevel gear applications, angle gearboxes play a crucial role in ensuring efficient and reliable mechanical operations.

Handling Variations in Input and Output Angles with Angle Gearboxes

Angle gearboxes are specifically designed to handle variations in input and output angles, allowing for efficient redirection of rotational motion. They achieve this through the use of bevel gears and hypoid gears. Here’s how they handle such variations:

- Bevel Gears: Angle gearboxes equipped with bevel gears can handle changes in input and output angles by using intersecting axes. These gears have conical shapes and teeth that are cut along the cone surface. When the input shaft’s bevel gear meshes with the output shaft’s bevel gear, the intersecting angles allow for smooth power transmission even when the axes are not aligned.

- Hypoid Gears: Hypoid gear arrangements in angle gearboxes can handle larger variations in input and output angles compared to bevel gears. Hypoid gears have helical teeth and axes that are offset from each other. This offset allows for greater flexibility in handling non-parallel input and output shafts.

By employing these gear types, angle gearboxes can effectively manage variations in input and output angles, ensuring that rotational motion is smoothly redirected without compromising efficiency or causing excessive wear on the gears.

editor by CX 2023-11-27