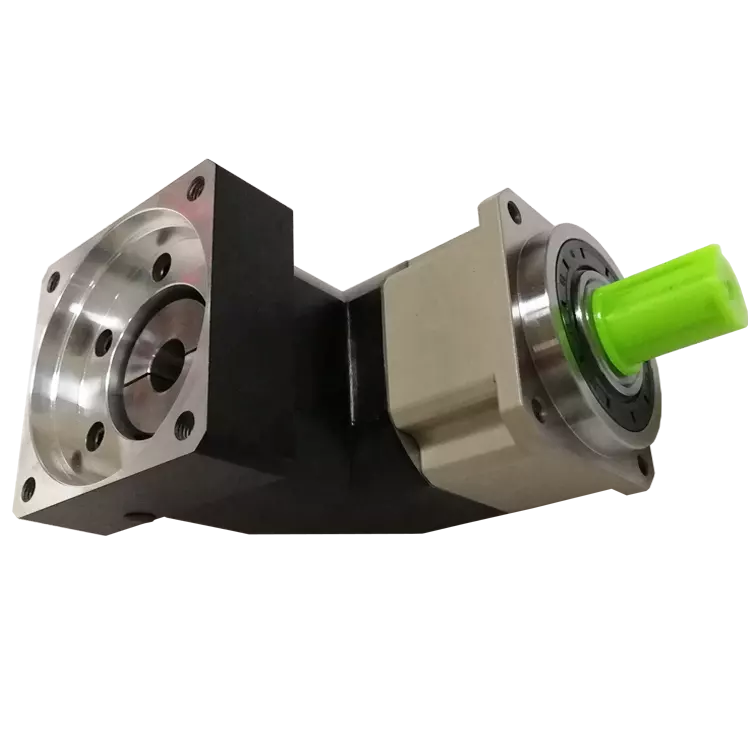

Product Description

For over 12 years, spiral bevel gearboxes from SIJIE have been the market leader for high-quality, reliable, versatile right-angle gearboxes.

We can also manufacture a special bevel gearbox to fit all your demands of the application.

SIJIE spiral bevel gearboxes are offered in 8 types of housing sizes and 6 types of gear ratios, which can be constructed with lots of shaft configurations and oriented in any direction to easily integrate into your machine design.

All the shaft configurations are suitable for Casting iron, stainless steel, and aluminum version bevel gearboxes.

Spiral Bevel Gearbox Specifications

| Model | Input Speed (RPM) | Gear Ratio 1:1 | Gear Ratio 2:1 | Gear Ratio 3:1 | Gear Ratio 4:1 | Gear Ratio 5:1 | |||||

| Power | Torque | Power | Torque | Power | Torque | Power | Torque | Power | Torque | ||

| ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ( KW ) | ( N.m ) | ||

| SJV-090 | 2000 | 7.55 | 33.6 | 4.2 | 38.57 | 2.85 | 40.39 | 2.15 | 39.76 | 1.4 | 34.56 |

| 1500 | 6 | 38.2 | 3.35 | 42.66 | 2.2 | 42.02 | 1.65 | 42.02 | 1.1 | 35.02 | |

| 1000 | 4.3 | 41.07 | 2.35 | 44.89 | 1.5 | 43.02 | 1.15 | 43.93 | 0.75 | 35.81 | |

| 750 | 3.4 | 43.29 | 1.8 | 45.84 | 1.2 | 45.84 | 0.87 | 44.19 | 0.58 | 36.93 | |

| SJV-110 | 2000 | 13.8 | 63 | 7.9 | 72 | 5.6 | 80 | 3.75 | 70.1 | 2.95 | 71.3 |

| 1500 | 11 | 70 | 6.3 | 80.2 | 4.45 | 85 | 2.9 | 73.9 | 2.35 | 74.8 | |

| 1000 | 7.87 | 75 | 4.45 | 85 | 3.1 | 88.8 | 2 | 76.4 | 1.6 | 76.4 | |

| 750 | 6.15 | 78.3 | 3.45 | 87.9 | 2.4 | 91.7 | 1.55 | 78.9 | 1.25 | 79.6 | |

| SJV140 | 2000 | 29.9 | 128.6 | 14.1 | 133.3 | 10.1 | 136.8 | 6.8 | 125.3 | 5.05 | 115.2 |

| 1500 | 23.9 | 152.2 | 11.1 | 141.3 | 7.95 | 151.8 | 5.3 | 135 | 3.95 | 125.7 | |

| 1000 | 17.2 | 164.3 | 7.85 | 149.9 | 5.6 | 160.4 | 3.75 | 143.3 | 2.75 | 131.3 | |

| 750 | 13.4 | 170.6 | 6.2 | 157.9 | 4.4 | 168.1 | 2.95 | 150.3 | 2.1 | 133.7 | |

| SJV-170 | 2000 | 49.2 | 180.1 | 26.2 | 224.7 | 18.2 | 235.2 | 10.5 | 179.5 | 8.05 | 170.9 |

| 1500 | 39.3 | 250.2 | 20.8 | 264.9 | 14.4 | 275 | 8.4 | 213.9 | 6.45 | 205.3 | |

| 1000 | 28.8 | 275 | 14.9 | 284.6 | 10.1 | 289.4 | 5.9 | 225.4 | 4.5 | 214.9 | |

| 750 | 22.8 | 290.3 | 11.6 | 295.4 | 7.8 | 298 | 4.55 | 231.7 | 3.45 | 219.7 | |

| SJV-210 | 2000 | 84 | 336.7 | 52.4 | 480.2 | 34.9 | 428.3 | 23.3 | 417.6 | 15.9 | 350.2 |

| 1500 | 67.5 | 429.8 | 43.2 | 550.1 | 27.7 | 529.1 | 18.5 | 471.1 | 12.7 | 404.3 | |

| 1000 | 50.5 | 482.3 | 31.4 | 599.7 | 20 | 573 | 13.4 | 511.9 | 9 | 429.8 | |

| 750 | 40.8 | 519.5 | 25.2 | 641.8 | 15.7 | 599.7 | 10.4 | 529.7 | 6.95 | 442.5 | |

| SJV-240 | 2000 | 111 | 475.8 | 71.5 | 643.7 | 52.4 | 695.2 | 37.7 | 652.3 | 28.9 | 643.8 |

| 1500 | 90.5 | 576.2 | 58.5 | 744.9 | 41.9 | 800.3 | 30.2 | 769.1 | 23.4 | 744.9 | |

| 1000 | 68 | 649.4 | 41.9 | 800.3 | 30.2 | 865.2 | 21.7 | 828.9 | 16.4 | 783.1 | |

| 750 | 54.5 | 694 | 33.8 | 860.8 | 23.6 | 901.5 | 17.1 | 871 | 13 | 827.7 | |

| SJV-280 | 2000 | 168 | 837.5 | 107 | 961.4 | 73 | 957 | 47.6 | 870.4 | 39.4 | 890.5 |

| 1500 | 156 | 993.2 | 88 | 1121 | 58.5 | 1117 | 38.5 | 980.5 | 31.4 | 999.6 | |

| 1000 | 115 | 1098 | 64.5 | 1232 | 42.4 | 1215 | 27.5 | 1051 | 22.4 | 1070 | |

| 750 | 94.2 | 1199 | 51 | 1299 | 33.5 | 1280 | 21.7 | 1105 | 17.7 | 1127 | |

Company Informations:

Factory Apprarance Production Workshop

Assembly Workshop Inventory Workshop

SIJIE Team Gearbox Shipment

Why SIJIE cubic spiral bevel gearbox?

1: High-quality, low Backlash, quiet noise, smooth running, high torque bevel gearbox professional manufacturer since 2008.

2: The wide range of bevel gearbox product lines can meet the application needs of customers to the greatest extent.Gearbox housing size is from 065 to 280. Casting iron, stainless steel, and aluminum version gearboxes can be manufactured according to customers’ requirements.

3: Strict quality control has been from the beginning to end at SIJIE. All the cubic bevel gearboxes will be tested in our factory accordingto the more than 30 items checking list before shipping.

4: SIJIE cubic type bevel gearbox has 13 months warranty period, during the warranty period, any problem with “SIJIE” products,after we confirmed, we will guide the customer to fix or ship a new 1 to replace it in 1-3 working days.

5: SIJIE kept a large inventory of cubic spiral bevel gearbox parts to make sure all the standard orders can be shipped in 7 working days.

6: Our Experienced Engineer Team can design the bevel gearbox drawings to fit all your demands in 2 hours. Small-quantity OEM/ODM orders also can be accepted by SIJIE. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Hardness: | Hardened Tooth Surface |

| Step: | Single-Step |

| Gear Ratios: | 1:1, 2:1, 3:1, 4:1, 5:1 |

| Configurations: | 2-Way, 3-Way, 4-Way Shafts |

| Samples: |

US$ 95/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Disadvantages and Limitations of Angle Gearbox Systems

While angle gearbox systems offer numerous advantages, there are also some disadvantages and limitations to consider:

- Complex Design: Angle gearboxes can have a more complex design compared to standard gearboxes, which can make them harder to manufacture, assemble, and maintain. This complexity can also lead to higher production costs.

- Efficiency Loss: Due to the multiple gear stages and changes in direction of motion, angle gearboxes can experience higher friction and efficiency losses compared to straight-line gearboxes. This can result in some energy loss and heat generation.

- Space Constraints: The design of angle gearboxes often requires more space to accommodate the multiple gear stages and components, which can be a limitation in applications with limited space.

- Increased Maintenance: The complex design of angle gearboxes can lead to increased maintenance requirements. Components such as bearings, seals, and gears may need more frequent inspections and replacements.

- Cost: Angle gearboxes can be more expensive to produce and maintain due to their intricate design and the precision required in manufacturing. This can impact the overall cost of the machinery or equipment in which they are used.

Despite these limitations, angle gearbox systems are chosen when their benefits outweigh their drawbacks for specific applications. Engineers and designers carefully assess the requirements of the application to determine if an angle gearbox is the optimal solution, taking into account factors such as space availability, load demands, efficiency considerations, and budget constraints.

Usage of Angle Gearboxes in Right-Angle and Bevel Gear Applications

Angle gearboxes are versatile components that can be effectively used for both right-angle and bevel gear applications. Here’s how they are utilized in each context:

Right-Angle Applications: Angle gearboxes are commonly used in right-angle applications where there is a need to transmit motion at a 90-degree angle. They efficiently change the direction of rotational motion without the need for additional components or complex mechanical arrangements. This makes them suitable for various industrial machinery, conveyors, and equipment where space constraints and changes in motion direction are important considerations.

Bevel Gear Applications: Angle gearboxes are also employed in bevel gear applications. Bevel gears are used to transmit motion between intersecting shafts, and angle gearboxes with bevel gears are designed to handle this type of motion transmission. They can efficiently transfer motion and torque between shafts that are not parallel, enabling smooth power transmission even when the input and output shafts are at an angle other than 90 degrees.

Whether it’s changing the direction of motion in right-angle applications or facilitating motion transmission between non-parallel shafts in bevel gear applications, angle gearboxes play a crucial role in ensuring efficient and reliable mechanical operations.

Contribution of Angle Gearboxes to Changing Rotational Direction

Angle gearboxes, also known as bevel gearboxes, play a significant role in altering the direction of rotational motion in mechanical systems. They achieve this by utilizing specially designed bevel gears that have their teeth cut at an angle, typically 90 degrees. This angled configuration allows the gears to mesh smoothly while transmitting power between intersecting shafts at different angles.

Here’s how angle gearboxes contribute to changing the direction of rotational motion:

- Meshing of Bevel Gears: Angle gearboxes consist of two bevel gears with intersecting shafts. The gears have teeth that are cut in a way that enables them to mesh together when the shafts are at an angle, usually perpendicular to each other.

- Transfer of Torque: When one bevel gear receives rotational input from a source, it transmits torque to the second bevel gear through the meshing of their teeth. This transfer of torque allows power to be transmitted from one shaft to the other.

- Change in Direction: As the first bevel gear rotates, it drives the second bevel gear to rotate in a direction that is perpendicular to the input shaft. This change in direction of rotation is a fundamental function of angle gearboxes.

- Multiple Configurations: Angle gearboxes come in various configurations to accommodate different angles between shafts, including right angle (90 degrees), acute angles, and obtuse angles. This versatility allows them to adapt to diverse applications.

Angle gearboxes are crucial components in mechanical systems where the input and output shafts need to be oriented at different angles. Their ability to smoothly change the direction of rotational motion makes them valuable in a wide range of industries and applications.

editor by CX 2024-03-27