Product Description

Product Description

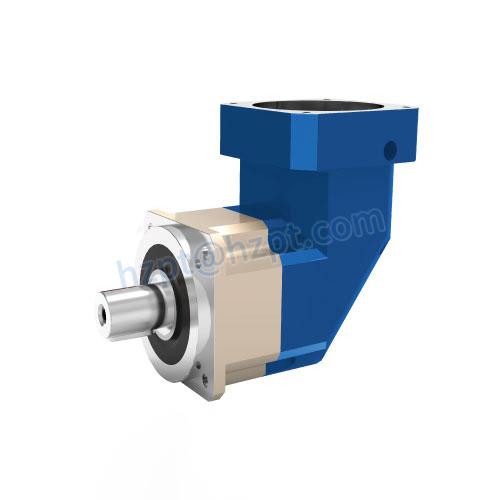

The NDR110 series planetary gearboxes are designed and machined as a single unit with special tapered roller bearings to provide high radial load, high torque, ultra-precision, and small size. The ND series uses in highly rigid industries such as fiber optic laser equipment, floor track equipment, robot seventh axis, Parallel robots (spider hand) machine tools, and rotating arms.

Product Name: High Precision Planetary Reducer

Product Series: NDR110 Series

Product features: high torque, high load, ultra-precision, small size

Product Description:

Integrated design concept with high-strength bearings ensure the product itself is durable and efficient

A variety of output ideas such as shaft output, flange and gear are available.

Reduction ratios ranging from 4 to 200

Frame design: increases torque and optimizes power transmission

Optimised selection of oil seals: reduces friction and laminate transmission efficiency

Protection class IP65

Warranty: 2 years

Our Advantages

High torque

High load

Ultra-precision

Small size

Space saving

Detailed Photos

Product Parameters

| Segment number | Single segment | ||||||||

| Ratio | i | 25 | 35 | 40 | 50 | 70 | 100 | 140 | 200 |

| Rated output torque | Nm | 310 | 280 | 250 | 310 | 280 | 210 | 280 | 210 |

| Emergency stop torque | Nm | Three times of Maximum Output Torque | |||||||

| Rated input speed | Rpm | 4000 | |||||||

| Max input speed | Rpm | 8000 | |||||||

| Ultraprecise backlash | arcmin | ≤4 | |||||||

| Precision backlash | arcmin | ≤7 | |||||||

| Standard backlash | arcmin | ≤9 | |||||||

| Torsional rigidity | Nm/arcmin | 82 | |||||||

| Max.bending moment | Nm | 430 | |||||||

| Max.axial force | N | 2990 | |||||||

| Service life | hr | 30000(15000 under continuous operation) | |||||||

| Efficiency | % | ≥92% | |||||||

| Weight | kg | 9.8 | |||||||

| Operating Temperature | ºC | -10ºC~+90ºC | |||||||

| Lubrication | Synthetic grease | ||||||||

| Protection class | IP64 | ||||||||

| Mounting Position | All directions | ||||||||

| Noise level(N1=3000rpm,non-loaded) | dB(A) | ≤68 | |||||||

| Rotary inertia | Kg·cm² | 2.25 | 1.87 | ||||||

Applicable Industries

Packaging Machinery Mechanical Hand Textile Machinery

Non Standard automation Machine Tool Printing Equipment

| Application: | Motor, Machinery, Marine, Agricultural Machinery, CNC Machine |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Layout: | Plantery Gearbox |

| Hardness: | Hardened Tooth Surface |

| Installation: | All Directions |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Ensuring Precision of Gear Tooth Profiles in Angle Gearboxes

Manufacturers employ various techniques and processes to ensure the precision of gear tooth profiles in angle gearboxes:

- Advanced Manufacturing Technologies: Modern manufacturing technologies such as CNC machining and gear hobbing are used to precisely shape gear teeth. Computer-controlled processes enable accurate replication of gear tooth profiles.

- High-Quality Materials: High-quality materials are selected to create gears that can withstand the stresses and loads they will experience during operation. High-grade metals and alloys are commonly used.

- Quality Control and Inspection: Rigorous quality control measures involve inspecting gear tooth profiles using specialized equipment like coordinate measuring machines (CMMs) and gear analyzers. This ensures that the dimensions and profiles meet the required specifications.

- Tooth Profile Design Software: Engineering software is used to design gear tooth profiles with precision. Computer-aided design (CAD) software allows engineers to model gear teeth accurately before manufacturing.

- Heat Treatment: Gears are often subjected to heat treatment processes such as carburizing or nitriding to enhance their surface hardness, durability, and resistance to wear.

The combination of advanced manufacturing techniques, strict quality control, and the use of quality materials helps manufacturers achieve the necessary precision in gear tooth profiles. This precision is critical to ensure smooth and efficient power transmission, minimal noise, and extended gearbox lifespan.

Efficient Power Transmission and Motion Control with Angle Gearboxes

Angle gearboxes play a crucial role in ensuring efficient power transmission and precise motion control in various mechanical systems. They achieve this through several mechanisms:

- Gear Arrangement: Angle gearboxes use a combination of gears, such as bevel gears, worm gears, or hypoid gears, to redirect the rotational motion efficiently while changing the direction of the output shaft.

- High Gear Ratios: Many angle gearboxes incorporate high gear ratios, allowing them to convert high-speed, low-torque input into lower-speed, higher-torque output. This is particularly useful in applications where high torque is required, such as heavy machinery or industrial equipment.

- Precision Engineering: Angle gearboxes are designed with precision to minimize backlash and gear play. This ensures accurate and reliable motion control, which is essential in applications demanding precise positioning and synchronization.

- Lubrication and Sealing: Proper lubrication and sealing in angle gearboxes reduce friction and wear, contributing to efficient power transmission. Well-maintained gearboxes experience less energy loss due to friction and heat generation.

- Material Selection: High-quality materials and advanced manufacturing techniques are used to construct angle gearboxes. This ensures that components can handle the loads and stresses without excessive wear or failure, promoting efficient power transfer.

- Alignment and Assembly: Accurate alignment during the assembly of angle gearboxes prevents misalignment-related losses and reduces strain on gears and bearings, resulting in smoother power transmission.

Whether in industrial machinery, automotive systems, or other mechanical applications, angle gearboxes contribute to efficient power transmission and motion control by optimizing gear arrangements, minimizing energy losses, and providing reliable performance over extended periods.

Types of Angle Gearboxes and Their Functions

Angle gearboxes, also known as bevel gearboxes, come in different types, each designed for specific functions and applications. The various types of angle gearboxes include:

- Straight Bevel Gearbox: This type of angle gearbox features straight-cut bevel gears with intersecting shafts set at a 90-degree angle. It is commonly used for changing the direction of rotational motion in applications such as automotive differentials and power tools.

- Spiral Bevel Gearbox: Spiral bevel gearboxes utilize spiral-cut bevel gears that offer smoother and quieter operation compared to straight-cut gears. They are employed in applications where reduced noise and improved load-carrying capacity are important, such as in heavy machinery and vehicles.

- Skew Bevel Gearbox: Skew bevel gearboxes have shafts set at an angle other than 90 degrees. They are used in applications where the intersecting shafts do not align at a right angle. Skew bevel gears are often found in industrial machinery and equipment that requires a specific angle of transmission.

- Hypoid Gearbox: Hypoid gearboxes feature hypoid gears, which are a variation of bevel gears with offset axes. This design allows the gears to mesh smoothly while reducing noise and increasing torque transmission efficiency. Hypoid gearboxes are commonly used in automotive applications like rear-wheel-drive systems.

- Angular Bevel Gearbox: Angular bevel gearboxes are designed for applications where the angle between the input and output shafts is adjustable. They are used in situations where the desired transmission angle can be changed to achieve specific mechanical requirements.

Each type of angle gearbox serves a distinct purpose, catering to various industries and applications. Their designs are optimized to provide efficient motion transmission, reliable performance, and the ability to accommodate different angles and loads.

editor by CX 2023-10-21