Product Description

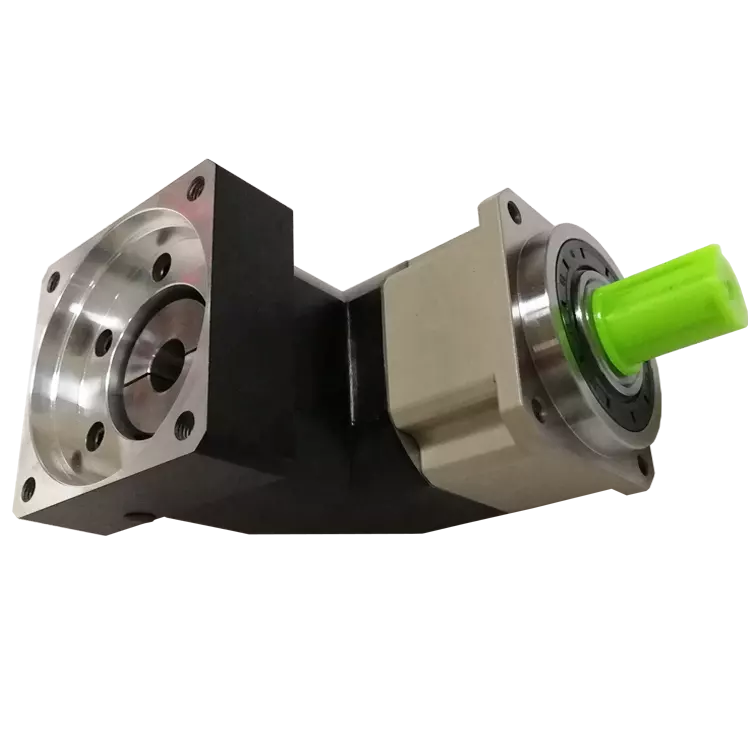

Hydraulic Gearbox Mini Reversing Cycloidal Electric Car 11200 Marine Automatic 90 Right Angle Baler Extruder Stainless Steel Tractor

Application of Hydraulic Gearbox

Hydraulic gearboxes are used in a variety of applications where high torque and low speed are required. They are often used in construction equipment, such as excavators and bulldozers, as well as in industrial machinery, such as presses and cranes.

Hydraulic gearboxes work by using hydraulic fluid to transmit power from a motor to a rotating shaft. The fluid is pumped through a series of gears, which turn the shaft at a slower speed but with greater torque. This allows the hydraulic gearbox to provide the high torque and low speed that is required for many applications.

Here are some of the applications of hydraulic gearboxes:

- Construction equipment: Hydraulic gearboxes are used in construction equipment, such as excavators and bulldozers, to provide the high torque and low speed that is required for moving heavy objects.

- Industrial machinery: Hydraulic gearboxes are used in industrial machinery, such as presses and cranes, to provide the high torque and low speed that is required for operating heavy machinery.

- Other: Hydraulic gearboxes are also used in a variety of other applications, such as off-road vehicles, marine equipment, and wind turbines.

Hydraulic gearboxes are a versatile and reliable type of gearbox that can be used in a variety of applications. They are a good choice for applications where high torque and low speed are required.

Here are some of the advantages of using hydraulic gearboxes:

- They can transmit high torque at low speeds.

- They are compact and lightweight.

- They are durable and can withstand harsh environments.

- They are easy to maintain.

Here are some of the disadvantages of using hydraulic gearboxes:

- They can be expensive to purchase and install.

- They can be noisy in operation.

- They can be sensitive to leaks and can be damaged if they are not properly operated.

Overall, hydraulic gearboxes are a versatile and reliable type of gearbox that can be used in a variety of applications. They are a good choice for applications where high torque and low speed are required.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Disadvantages and Limitations of Angle Gearbox Systems

While angle gearbox systems offer numerous advantages, there are also some disadvantages and limitations to consider:

- Complex Design: Angle gearboxes can have a more complex design compared to standard gearboxes, which can make them harder to manufacture, assemble, and maintain. This complexity can also lead to higher production costs.

- Efficiency Loss: Due to the multiple gear stages and changes in direction of motion, angle gearboxes can experience higher friction and efficiency losses compared to straight-line gearboxes. This can result in some energy loss and heat generation.

- Space Constraints: The design of angle gearboxes often requires more space to accommodate the multiple gear stages and components, which can be a limitation in applications with limited space.

- Increased Maintenance: The complex design of angle gearboxes can lead to increased maintenance requirements. Components such as bearings, seals, and gears may need more frequent inspections and replacements.

- Cost: Angle gearboxes can be more expensive to produce and maintain due to their intricate design and the precision required in manufacturing. This can impact the overall cost of the machinery or equipment in which they are used.

Despite these limitations, angle gearbox systems are chosen when their benefits outweigh their drawbacks for specific applications. Engineers and designers carefully assess the requirements of the application to determine if an angle gearbox is the optimal solution, taking into account factors such as space availability, load demands, efficiency considerations, and budget constraints.

Selecting the Right Angle Gearbox for an Application

Choosing the appropriate angle gearbox for a specific application involves considering several key factors to ensure optimal performance and reliability:

- Application Requirements: Determine the required torque, speed, and power output of the gearbox to match the demands of the application.

- Input and Output Angles: Identify the desired input and output angles for the gearbox to ensure it can effectively redirect motion as needed.

- Space Constraints: Evaluate the available space to select a gearbox that fits within the allocated area.

- Gearbox Type: Choose the suitable gearbox type (e.g., right angle, bevel, worm, hypoid) based on the application’s specific needs.

- Load Conditions: Consider factors such as load variation, shock loads, and continuous vs. intermittent operation to determine gearbox durability.

- Environmental Conditions: Account for factors like temperature, humidity, and exposure to contaminants, which can affect gearbox performance and lifespan.

- Efficiency: Evaluate the gearbox’s efficiency, as lower efficiency may result in more energy consumption and heat generation.

- Mounting and Installation: Ensure that the gearbox can be easily mounted and integrated into the existing system.

- Maintenance and Servicing: Consider the ease of maintenance, accessibility to components, and availability of replacement parts.

- Budget: Compare the cost of the gearbox with its features and benefits to determine its overall value for the application.

By carefully considering these factors, engineers and designers can select the right angle gearbox that best meets the requirements of the specific application, ensuring optimal performance and longevity.

Contribution of Angle Gearboxes to Changing Rotational Direction

Angle gearboxes, also known as bevel gearboxes, play a significant role in altering the direction of rotational motion in mechanical systems. They achieve this by utilizing specially designed bevel gears that have their teeth cut at an angle, typically 90 degrees. This angled configuration allows the gears to mesh smoothly while transmitting power between intersecting shafts at different angles.

Here’s how angle gearboxes contribute to changing the direction of rotational motion:

- Meshing of Bevel Gears: Angle gearboxes consist of two bevel gears with intersecting shafts. The gears have teeth that are cut in a way that enables them to mesh together when the shafts are at an angle, usually perpendicular to each other.

- Transfer of Torque: When one bevel gear receives rotational input from a source, it transmits torque to the second bevel gear through the meshing of their teeth. This transfer of torque allows power to be transmitted from one shaft to the other.

- Change in Direction: As the first bevel gear rotates, it drives the second bevel gear to rotate in a direction that is perpendicular to the input shaft. This change in direction of rotation is a fundamental function of angle gearboxes.

- Multiple Configurations: Angle gearboxes come in various configurations to accommodate different angles between shafts, including right angle (90 degrees), acute angles, and obtuse angles. This versatility allows them to adapt to diverse applications.

Angle gearboxes are crucial components in mechanical systems where the input and output shafts need to be oriented at different angles. Their ability to smoothly change the direction of rotational motion makes them valuable in a wide range of industries and applications.

editor by CX 2023-10-21