Product Description

Product Advantages

|

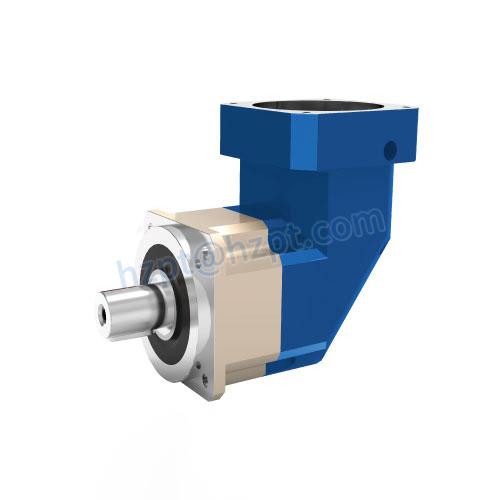

F Series Gearbox Reducer |

|

|

Product name |

F series of the gearbox hollow shaft model F107 oil seal transmission gearbox reducer reduction |

|

Warranty |

1 years |

|

Applicable Industries |

Manufacturing Plant |

|

Weight (KG) |

50KG |

|

Customized support |

OEM |

|

Gearing Arrangement |

Helical |

|

Output Torque |

1.8-2430N.M |

|

Input Speed |

1440, 2800,960,750 |

|

Output Speed |

0.5 to 200 |

|

Place of Origin |

China |

|

Product name |

F Series Parallel Shaft Gearbox Reducer |

|

Application |

Hardened Tooth Surface |

|

Installation |

Horizontal Type |

|

Layout |

Coaxial |

|

Gear Shape |

Helical |

|

Production Capacity |

800-1500PCS /Month |

|

Type |

Gear Reduction Motor |

|

Color |

Blue,Sliver or Customized |

|

Packing |

Wooden Box |

Six advantages

Our Advantages

–Modular design, wide transmission ratio coverage, fine and reasonable distribution; Force reducer

–There are 11 types of frame specifications from F.27-F.157, and the transmission power range is 0.12KW-200KW;

–The shape design is suitable for omnidirectional universal installation configuration;

–The transmission is relatively accurate, covering the range of 3.77-281.71, and can be selected as required;

–The gear is grinded by high-precision gear grinding machine, with balanced transmission, low noise, and interstage efficiency of 98%;

–The transmission ratio of the F.R.reducer is extended to 31431, which is specially designed for special low-speed occasions

Editing and broadcasting of main materials

–Box: cast iron;

–Gear: low carbon alloy steel, carbonitriding treatment (after fine grinding, keep the tooth surface hardness of 60HRC, hard layer thickness>0.5mm);

–Flat key: 45 steel, with surface hardness above 45HRC.

Surface painting:

–Cast iron: sprayed with RAL7031 grey blue paint.

Parameter editing broadcast

Power: 0.18KW~200KW

Torque: 3N · m ~ 22500N · m

F series parallel shaft reducer

F series parallel shaft reducer

Output speed: 0.06~374r/minF series parallel shaft reducer [1]

| Application: | Motor, Motorcycle, Machinery, Agricultural machine |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Expansion, Parallel |

| Gear Shape: | Bevel Gear |

| Step: | Single-Step |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

Customization of Angle Gearboxes for Industrial Needs

Yes, angle gearboxes can be customized to meet specific industrial needs and requirements. Manufacturers offer customization options to tailor angle gearboxes to the unique demands of various applications:

- Gear Ratio Selection: Gear ratio customization allows the gearbox to achieve the desired speed reduction or increase based on the specific application’s requirements.

- Mounting Configurations: Manufacturers can design angle gearboxes with various mounting options to ensure seamless integration into different machinery setups.

- Output Shaft Options: Customizing the output shaft design enables compatibility with specific components or systems.

- Sealing and Protection: Gearboxes can be customized with specialized sealing and protection mechanisms to ensure optimal performance in harsh environments.

- Materials and Coatings: Depending on the application’s demands, manufacturers can select appropriate materials and coatings for enhanced durability and corrosion resistance.

- Special Features: Custom features such as built-in sensors, lubrication systems, or noise reduction measures can be added to meet specific operational requirements.

Customization ensures that angle gearboxes can effectively fulfill their intended roles in various industries, from automotive and aerospace to robotics and manufacturing. By tailoring the gearbox design to match specific needs, companies can achieve optimal performance, efficiency, and reliability in their applications.

Selecting the Right Angle Gearbox for an Application

Choosing the appropriate angle gearbox for a specific application involves considering several key factors to ensure optimal performance and reliability:

- Application Requirements: Determine the required torque, speed, and power output of the gearbox to match the demands of the application.

- Input and Output Angles: Identify the desired input and output angles for the gearbox to ensure it can effectively redirect motion as needed.

- Space Constraints: Evaluate the available space to select a gearbox that fits within the allocated area.

- Gearbox Type: Choose the suitable gearbox type (e.g., right angle, bevel, worm, hypoid) based on the application’s specific needs.

- Load Conditions: Consider factors such as load variation, shock loads, and continuous vs. intermittent operation to determine gearbox durability.

- Environmental Conditions: Account for factors like temperature, humidity, and exposure to contaminants, which can affect gearbox performance and lifespan.

- Efficiency: Evaluate the gearbox’s efficiency, as lower efficiency may result in more energy consumption and heat generation.

- Mounting and Installation: Ensure that the gearbox can be easily mounted and integrated into the existing system.

- Maintenance and Servicing: Consider the ease of maintenance, accessibility to components, and availability of replacement parts.

- Budget: Compare the cost of the gearbox with its features and benefits to determine its overall value for the application.

By carefully considering these factors, engineers and designers can select the right angle gearbox that best meets the requirements of the specific application, ensuring optimal performance and longevity.

Variations in Angle Gearbox Designs for Specific Tasks and Applications

Yes, angle gearbox designs can vary to suit specific tasks and applications across different industries. Manufacturers offer a range of angle gearbox configurations to address various requirements. Some common variations include:

- Right Angle Gearboxes: These angle gearboxes have input and output shafts at a 90-degree angle. They are often used in applications where space is limited, such as conveyor systems and packaging machinery.

- Worm Gear Angle Gearboxes: These gearboxes incorporate a worm gear arrangement, providing high gear reduction ratios. They are suitable for applications that require precise speed control, such as conveyor systems and material handling equipment.

- Bevel Gear Angle Gearboxes: Bevel gearboxes use intersecting shafts and conical gears to redirect motion at different angles. They are commonly found in automotive drivetrains, printing machines, and power tools.

- Hypoid Gear Angle Gearboxes: Hypoid gearboxes feature offset axes and helical gear teeth, allowing them to handle larger variations in input and output angles. They are used in automotive applications, heavy machinery, and industrial equipment.

- Customized Angle Gearboxes: Some manufacturers offer customized angle gearbox solutions tailored to specific applications. These gearboxes are designed to meet unique requirements, such as specific torque, speed, or space limitations.

Overall, the variations in angle gearbox designs enable them to be versatile and adaptable to a wide range of tasks and applications, making them an essential component in many industries.

editor by CX 2023-10-18